Behind The Scenes at Allrush – Heat Transfer Printing

In our last blog post, we shared a behind the scenes look at how to create custom clothing using a silkscreen. We’re back again with a whole new method… but this time, we’re bringing the heat!

Heat transfer printing is a newer method of fabric decoration that uses heat, rather than paint, to print your image. Remember 10-15 years ago, when iron-on printable paper was all the rage? Similar idea, but these days the execution is far better.

Here’s how we do it at Allrush:

Part 1: Decide on a Print

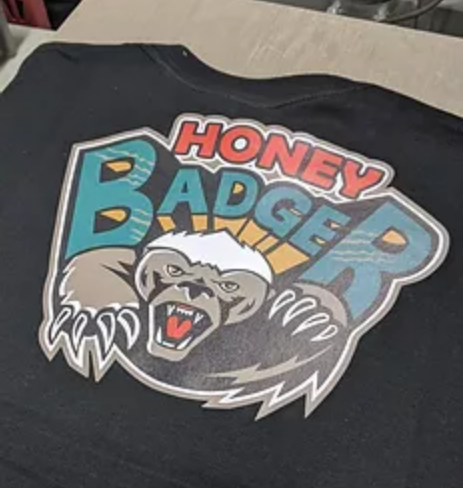

- We choose an image, graphic or text to print – or you choose one for us.

- We print the image of our special heat transfer paper, in reverse so it goes on the right way.

- We trim the paper to the appropriate size and shape.

Part 2: Prep the Machine

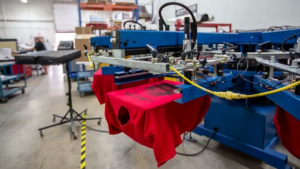

- We use a special heat press machine to transfer the image. For each type of material and paper, we use a different heat setting.

- Set the pressure. The thinner the material, the more pressure we use to ensure it transfers perfectly.

- We set the timer to allow the perfect time for the design to transfer.

Part 3: Transfer the Design

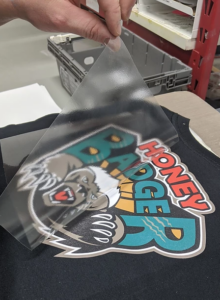

- We place your chosen fabric on the machine face up.

- We place the design over the fabric, lined up to where you’d like the design to be.

- Close the press and press the start button.

- Once the timer goes off, we remove your fabric and peel off your design. Once its cooled, you’re ready to go!

There you have it! This is a fun way to create custom fabrics far easier and less expensive than silk screening.

If you, like most of us, would rather spend your weekends watching Disney+ than doing DIY projects at home, check out the number of custom printing options at Allrush. Let us handle it, so you don’t have to.